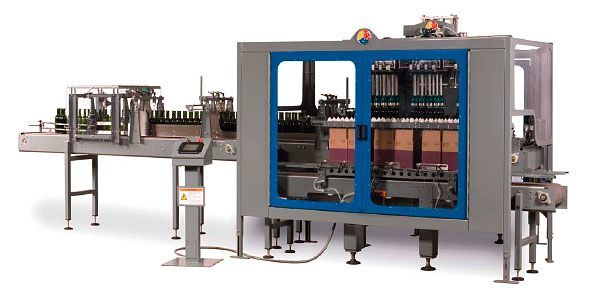

According to cGMP an installation qualification is documented verification that all aspects of a system, facility, utility or equipment that can affect product quality are installed according to specifications and design criteria.

When developing an IQ for your equipment qualification activities there are a number of aspects that need to be considered through the qualification process including:

Equipment Verification

- Equipment Make

- Equipment Model

- Equipment Serial Number

Drawing List & Documentation

- Update and As-Built

- P&ID’s

- Wiring/Logic/Loop Diagrams, Plan Viewr/li>

Note: Can be completed during SAT.

Equipment Install Verification

- Ensure environment is suitable – Fit For Use

- Accessible for cleaning/maintenance – Fit For Use

- Appears clearly labelled (ID, Controls, Safety)

Materials of Construction

- Includes lubricants (food grade – USDA H1) – Fit For Use

- All product contact parts (i.e Pump, Filler, Mix Tank) – Fir For Use

- Attach material certs (preferred) or manufacturer material certification

Utilities Verification

- All critical utilities required for proper operation of equipment (i.e electrical, water, compressed air, etc) – Fit For Use

Computerised Controls HW/SW

- For PLC or complex controls systems

- PLC software (i.e title, version)

- Hardware – make/model (i.e PLC, OIT, I/O Boards, Power Supplies)

Calibration

- Critical process devices & test equipment

- Calibration for all process devices (Temp, Pressure, etc)

- Any devices used in execution or measuring data (tachometer, caliper, etc)

Preventive Maintenance

- Document all PM’s

- Must be a scheduled frequency

Spare Parts

- Critical spares should be identified

- List of spare parts should be available in the maintenance shop and stocked – Fit For Use

- Product contact materials

Equipment Procedures

- Equipment operation SOP’s – Fit For Use

- Equipment use logs

- Cleaning SOP’s – Fit For Use

I/O PLC Connectivity

- All PLC I/O’s

- Can be performed by vendor or during SAT

- Can be printed with “Performed by” sign-off/date y vendor

- Empty addresses can be N/A’d

- Simulated or real-time testing

- Simulate signal with software (i.e force signal in PLC/RS Logix)

- Manipulate field device (i.e obstruct or “make” photo-eye)

- Simulate signal with equipment/instrument (i.e strobe generator)

- Manipulate using OIT