Precision is important in all aspects of human life. Evolution could have been a result of mankind becoming more and more precise with passing time. We have equipment to measure everything in life. These instruments need to work at optimal condition.

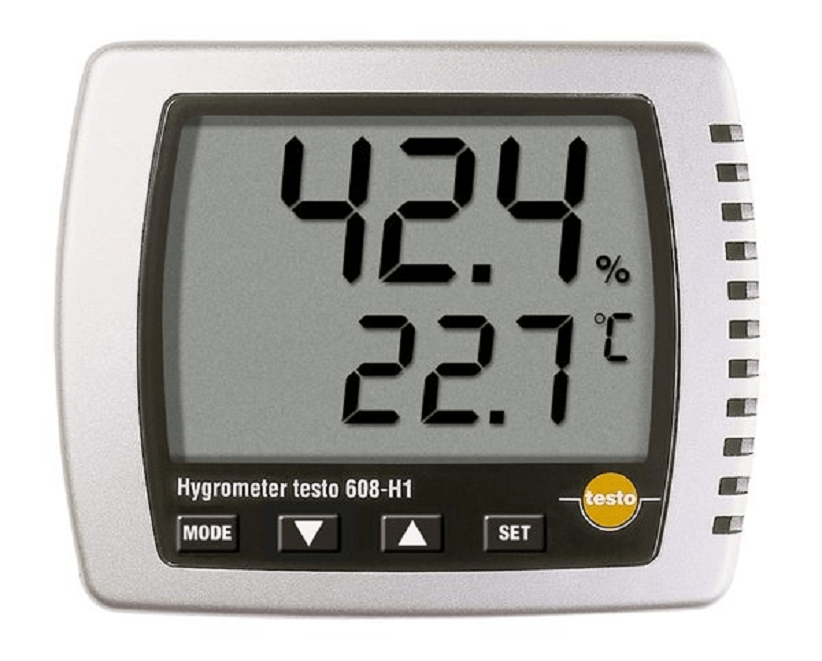

One such instrument is a Hygrometer. It is a device used to measure the moisture content in the atmosphere. As per the requirements of the customer, the calibration is done at the specific humidity points. The measurements used to calculate the humidity inside the hygrometers are:

- Data-acquisition application (used to measure the temperature and pressure of the saturator).

- The pressure inside the hygrometers, and the wet-gas.

- The wet-gas and dry-gas flows.

These measurements are then recorded in a spreadsheet and assembled in a workbook once all the data requested for the humidity points are requested. Then the new check standard data and the previous standard are compared to check the performance of the generator during the particular set of measurements. The final results in which the customer hygrometer humidity and HHG humidity are compared and placed in a calibration report.

Before the Start

The hygrometers are checked for cleanliness before they are connected to the hybrid generator. The hygrometer can be rejected for calibration is there is any dirt inside or on its fittings. If the chilled mirror hygrometers are used, then the hygrometer mirrors are cleaned with ethanol. The hygrometer is then tested for measurements.

By exposing the two gauges to the vaccum to measure their offset values, the pressure gauges of the hybrid generator are prepared for operation. It is done by correcting the zero offset of their readings.

Connection to Hybrid Generator

When the hygrometer is connected to the generator, a bypass tube which has an outlet to the room is connected parallel with the hygrometers. The proportion of the output gas which is bypassing the hygrometer is controlled using the valve which is on the bypass tube.

Measuring the pressure: The hygrometer pressure is measured by gauge which is located between the hygrometers and the bypass valve. If the humidity values exceed 15 °C (x = 1.6 × 10−3), the hygrometers are connected directly to the output of the 2-P generator, at a point downstream of the expansion valve. A heater tape is wrapped around the tubes which connect the output of the generator to the hygrometer if the desired dew points are above ambient temperature. The divided flow system with the multiplexer attached to the saturator is used if the desired humidity values are below a frost point of −15 °C.

Data Acquisition

- To achieve the highest efficiency, the order has to be planned so that as many points as possible can be taken at one saturator temperature.

- A computer application opens the spreadsheet after the hybrid generator is set to generate the desired humidity. It records the measurements for the hybrid generator, check standard and customer hygrometers in the spreadsheet at 30 s intervals for a total of 30 min.

- The application is run again if the data readings are not stable. The computer application is run twice to check the repeatability of the hygrometer for the calibration points with the highest and lowest humidity rates.

- The historical repeatability is assigned to the customer hygrometer if the first measurement s agree with the repeated measurements. The hygrometer is rejected or uncertainty is added and it all depends of the degree of the disagreement. The hygrometer repeatability is established after the first calibration is completed.

The Quality Check

If the stability and/or repeatability of the hygrometer is much s worse than the values which were given by the hygrometer specifications and the problems are unable to be corrected the hygrometer is rejected for calibration and returned to the customer.

Comparisons of at least two check standard points are made during the hygrometer calibration. If there is no check history of the lowest or highest standard customer calibration points, additional data which is closest to check standard point is taken. The new check standard data is compared to previous check standard data after the check standard data acquisition is complete.

Cross checks are made on the temperature and pressure measurement systems for the final saturator so that their measurements are within the stated uncertainties. This is done every four months.