It should be noted that the Site Acceptance Testing and the Operation Qualification Testing largely fulfil the same objectives (testing against the Functional Specification) and that these may usefully be performed at the same time or combined.

Note that decisions on the need for Factory and Site Acceptance Testing, the timing of these with the respect to the IQ and OQ and the possible combination of these may be taken in the early stages of the project. This decision should be documented as part of the Validation Master Plan or in the Project Quality Plan. If this is not the case, the relationship between Factory Acceptance Testing and Site Acceptance Testing should be documented in the Test Strategy.

Wherever possible it is desirable to reference the Supplier’s standard testing. Formal IQ and OQ Reports may reference the Supplier’s standard testing, which may be conducted as part of standard Factory or Site Acceptance Testing.

This may significantly reduce the scope of additional or duplicate user testing and assumes that the level of documented evidence is sufficient to support the validation case, which is in turn dependent upon the GxP criticality of the system (risk).

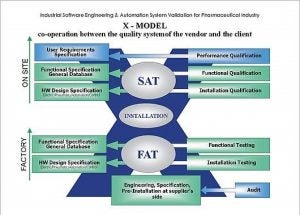

The relationship between the various Design Specifications, Test Specifications, FATs and SATs is shown in the following diagram below:

This diagram shows that:

- The development of Test Specifications takes place at the same time as the correspondent

Design Specification (this is of course done by a separate team). This reduces the project implementation time scales and helps ensure that the Functional and Design Specifications are testable. - Hardware Acceptance Testing is more likely to take place as part of the FAT, but some

elements of hardware testing may only be completed in situ, on site, during the SAT. - Software Module Testing and Package Configuration Testing are more likely to take place

as part of the FAT but some may only be completed on site during the SAT. - Software Integration Testing starts during the FAT, but some of this can only be conducted

on site during the SAT. - The results of the Hardware and Software Module Testing can all be referenced or

summarised as part of the Installation Qualification. - The results of the Package Configuration and Software Integration Testing can all be

referenced or summarised as part of the Operational Qualification. - Some System Acceptance Testing may be conducted as part of the FAT, but many

Acceptance Tests can only be conducted as part of the SAT.

The results of the System Acceptance Testing can be referenced or summarised as part of the Operation Qualification or Performance Qualification, depending upon the exact nature of the tests concerned.

Supplier Responsibility

It is the responsibility of the supplier to:

- Develop the Project Quality Plan that identifies the need for supplier specific testing.

- Develop the Hardware Test Specification (if appropriate).

- Develop the Software Module Test Specification (if appropriate).

- Develop the Software Integration Test Specification (if appropriate).

- Develop the Package Configuration Test Specification (if appropriate).

- Develop the System Acceptance Test Specification (if appropriate).

- Physically prepare for the actual tests.

- Conduct the appropriate tests (including recording the results and any retesting as

required).

User Responsibility

It is the responsibility of the user to:

- Define the need for the various System Test Specification(s) (usually in the Validation

Plan). - Physically prepare for those tests that will be performed on site.

- Assist with those System Acceptance Tests that will be performed on site.

- Witness the System Acceptance Tests (and any others that may need to be witnessed).

This may be no more that identifying that the System Test Specification(s) are a deliverable of the supplier and the user may choose to delegate all further responsibility to the supplier. This may be acceptable in the case of a reputable supplier with whom the user has worked before.

The System Acceptance Tests are the first major test of overall functionality of the system and it is usual for the user to witness the System Acceptance Tests in order to verify that the system to be supplied meets the agreed Functional Specification.

Where a user chooses not to witness some or all of the System Acceptance Tests the following may suffice as an acceptable alternative:

- Review and/or approve the final System Acceptance Test Specification prior to the System

Acceptance Tests commencing. - Review the results of the System Acceptance Tests and associated documentation as part of

the Operational Qualification.

Where the supplier audit has revealed deficiencies in the supplier’s testing regime the user may choose to review/approve other Test Specifications and/or witness additional tests (either at the premises of the supplier or on site). These may include the Software Module Tests, the Software Integration Tests, the Package Configuration Tests or the Hardware Tests.