The basic regulatory requirement is to provide pharmaceutical products of highest quality to the patients. A cleaning problem can have various consequences to health, economics, environment and regulatory approvals. Absence of good cleaning, leads to contaminated drugs, which pose risks for patients as well as manufacturing personnel.

Regulatory risk includes possible removal of authorization. Economical risk involves production delays and stock shortages or losses but also manifest as public relations problems for a company.

There are four main cleaning processes used in regulated environments. These include:

- Cleaning-in Place (CIP)

- Cleaning-out-of-place (COP)

- Manual Cleaning

- Immersion Cleaning

So whats the difference between all of these cleaning techniques?

Cleaning In Place (CIP)

Cleaning in place can be described as the cleaning of equipment and vessels at the same place without movement of them to a different place. The cleaning agents can be transferred to the vessel or equipment types either thorough fixed piping or flexible hoses.

The CIP process can consist of the following elements:

- Supply pump

- Return pump

- Heat exchanger with Black/Plant steam supply

- Chemical tanks i.e Acid, Alkali tanks

- Supply Pressure gauge or transmitter

- Supply temperature sensors

- Conductivity meter with sensor

Cleaning Out of Place (COP)

Cleaning Out of Place is defined as a method of cleaning equipment items by removing them from their operational area and taking them to a designated cleaning station for cleaning. It requires dismantling an apparatus, washing it in a central washing area using an automated system, and checking it at reassembly.

Manual Cleaning

Manual cleaning is the universal practise among the pharma and biopharma industries. The design, configuration and construction of equipment or the whole equipment which necessities the manual cleaning for the piece of equipment. The efficiency of the manual cleaning accomplished by training the cleaning operators, ensuring exact method of cleaning in the manual cleaning SOP, validating the method from different operators and verifying the procedure with interval of time.

The manual cleaning is dependent on,

- Concentration of detergent used

- Temperature of washing liquid

Immersion Cleaning

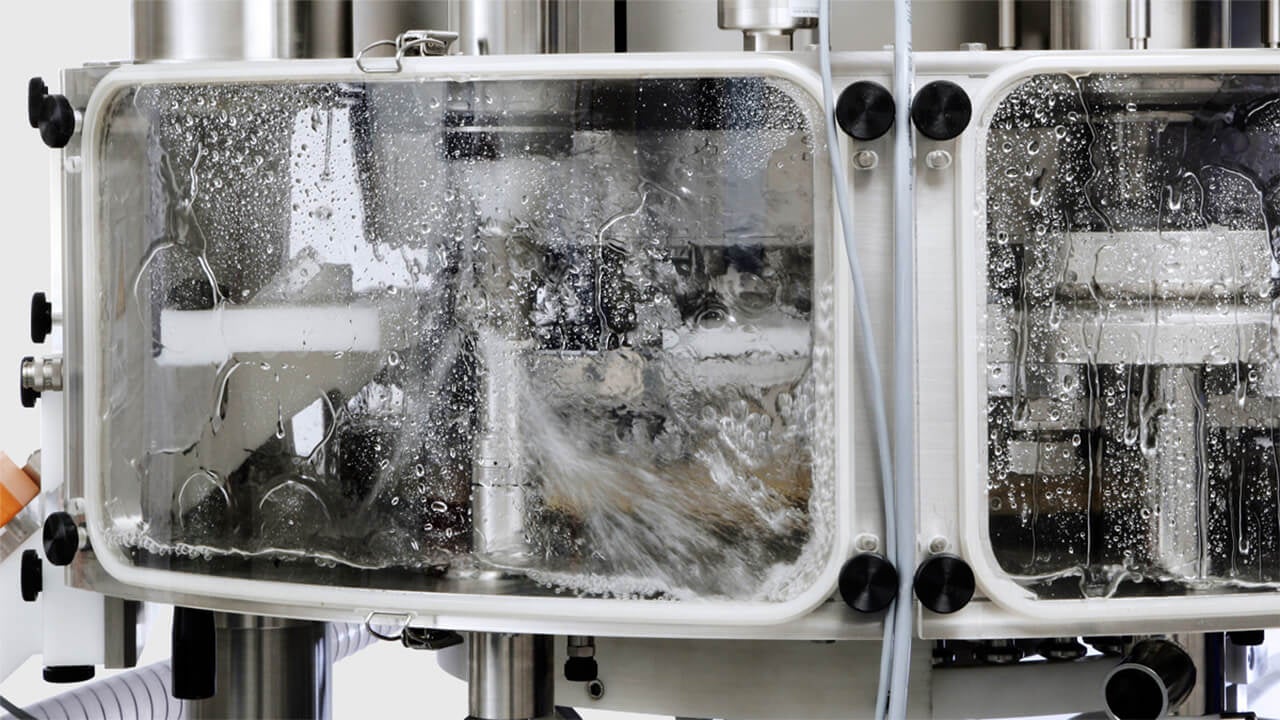

This is the type of cleaning in which the parts to be cleaned are placed in the cleaning solutions to come in contact with the entire surface of the parts.

Immersion cleaning is preferred for parts that must be placed in baskets and for processes requiring a long soaking time because of the type of contamination to be removed or the shape of the parts to be cleaned.

It is the most effective method, even if not the fastest one, and can be used with any type of cleaner for any process, heated or at room temperature. Immersion washers can be portable or stationary; single or multi-compartment; and are available with a variety of options, controls and valve configurations including CIP capability.

The important aspects during design of immersion washer should be

- To minimize cycle time

- Lower chemical usage

- Reduce water and utility costs

Performance for immersion cleaning can be improved by moving the parts within the liquid or with agitation of the liquid, mechanically or with the addition of ultrasonic energy.

Cleaning Validation Forum

If you would like to learn more about CIP or COP please read the following threads:

- Criteria of determination of cleaning of residue

- Post Cleaning Rinsing

- Cleaning Validation Conclusion Report

- Cleaning Validation Calculation

Cleaning Validation Help

If you would like help with a cleaning validation project please contact Premier Validation.