Changes to equipment and documentation is an integral part of the whole GMP process in any regulated facility. In this article we will discuss how equipment is designed in a GMP facility and how good documentation practices are an essential part of quality assurance and GMP.

The content of this article has been taken from module 7 of our eLearning module on Good Manufacturing Practices (cGMP) within the life sciences.

You can view this module in full by viewing the video below.

cGMP eLearning Module – Compelling, Engaging and Interactive

Equipment

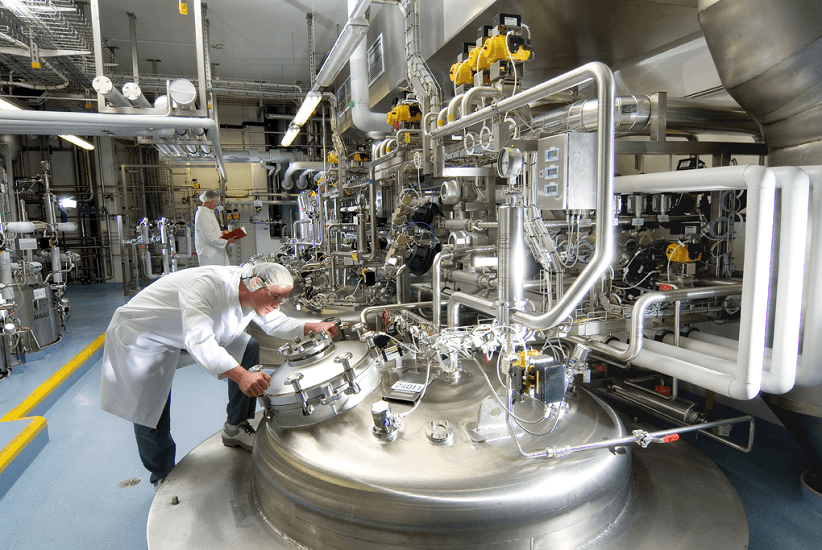

All equipment is designed, constructed and located to suit their intended use and to facilitate easy maintenance and cleaning.

Equipment is installed in such a way as to prevent any risk of error or of contamination, and cleaned according to detailed and written procedures and stored only in a clean and dry condition.

Production equipment should be designed in such a way as not to present any hazard to the products.

The parts of the production equipment that come into contact with the product must not be reactive, additive or absorptive to such an extent that it will affect the quality of the product and thus present any hazard.

Any defective equipment should, if possible, be removed from production and quality control areas, or at least be clearly labelled as defective. When not in use, equipment should be covered to ensure it remains clean.

Balances

Balances and measuring equipment of an appropriate range and precision should be available for production and quality control operations.

All measuring devices are required to be calibrated and checked at defined intervals by appropriate methods, and adequate records of such tests should be maintained.

Utilities

Fixed piping should be clearly labelled to indicate the contents and where applicable, the direction of flow.

Water pipes used in production (e.g. Purified Water, Water for Injection) are sanitised according to written procedures that detail the action limits for microbiological contamination and the measures to be taken.

Electrical circuits should be identified, and a record maintained of the load on each circuit to prevent inadvertent overload.

Documentation

Good Documentation Practices are an essential part of quality assurance and GMP.

It is important for a manufacturer to get the documentation right in order to get the product right.

GMP Documentation e.g. Site Master File, Specifications, Batch Manufacturing Formulae, Batch Manufacturing Records, Processing, Labelling, Packaging, Testing Instructions, Standard Operating Procedures, Protocols, Technical Agreements, Records, Certificates of Analysis, Reports etc. should contain the following attributes of a good document:

They should be:

- Attributable

- Legible

- Contemporaneous

- Original

- Accurate

- Complete

- Durable

- Corroborated

- Version Based

- Accessible

- And Authorized

Change Control

Change to GMP documentation, equipment, processes, systems, instrumentation, test methods, etc. are required to be controlled under a formal change control program.

This program must consist of Quality oversight to review the proposed changes, evaluate the potential impact of the change, determine any potential risk to product quality, and to establish the required level of supplemental validation/documentation required for the change.

In many instances, changes will also require submission to the Health Authority for approval of the change.

For example, changes impacting the submission documentation are subject to post approval change guidances according to the Health Authority regulations.

Change Control is a critical aspect of the GMP systems.

If you want to learn more about cGMP or if you want to evaluate our eLearning module for your company you can find more information here.